Why do some brushless DC motors run at incredible speed, some deliver strong torque, while others operate almost silently?

Although they all fall under the same name, types of BLDC motor vary widely in structure, sensing method, and drive waveform — and these differences directly shape performance.

As a manufacturer specialized in stator and rotor cores, we’ve seen how subtle changes in magnetic design or lamination precision can transform a motor’s behavior.

This article gives you a clear overview of the main types of brushless motor, their working principles, and how to choose the right one for your application.

Basic Structure of a BLDC Motor

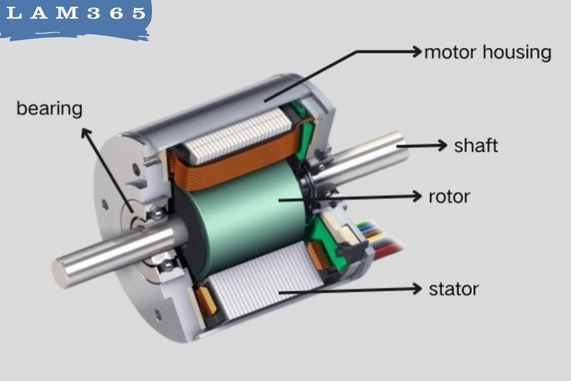

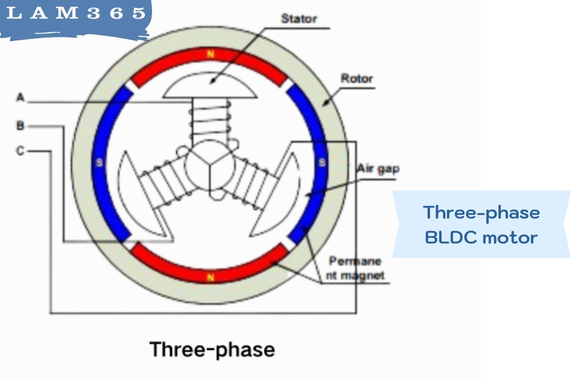

Every brushless DC motor (BLDC) consists of three main parts: stator, rotor, and housing.

- Stator (Magnetic Heart):

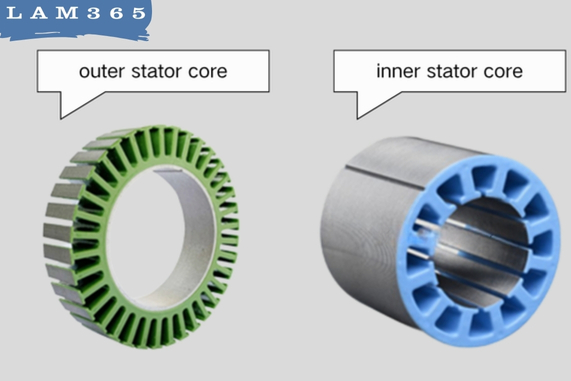

Made of laminated silicon steel sheets and copper windings, the stator generates the rotating magnetic field.

Its stator core quality directly affects efficiency, heat generation, and noise. A precise lamination stack reduces magnetic losses and ensures smooth magnetic flux.

- Rotor (Power Core):

The rotor core carries permanent magnets (usually NdFeB) that interact with the stator field to produce torque.

Depending on the design, magnets may rotate inside the stator (inner rotor BLDC motor) or surround it (outer rotor BLDC motor).

- Housing (Cooling & Protection):

The housing supports alignment, protects internal parts, and aids heat dissipation — often made from aluminum alloy for better thermal performance.

The main classification methods of BLDC motors

After understanding the internal structure of a BLDC motor, let’s look at a more important question — what makes different types of BLDC motor truly different?

Although all brushless DC motors work on the same principle — using electromagnetic force to rotate the rotor — their structure, sensing method, and driving waveform can vary a lot. These differences affect speed, torque, cooling ability, and manufacturing cost.

In general, BLDC motor types can be classified by:

- Structure (rotor position)

- Sensor configuration (sensored / sensorless)

- Phase number (single-phase / three-phase)

- Drive signal waveform (trapezoidal / sine wave)

Let’s start with the most visible and influential category — structure, which depends on where the rotor is placed.

1. Classification by Structure: Inner vs. Outer Rotor

Among all types of BLDC motor, the structural layout is the most obvious distinction.

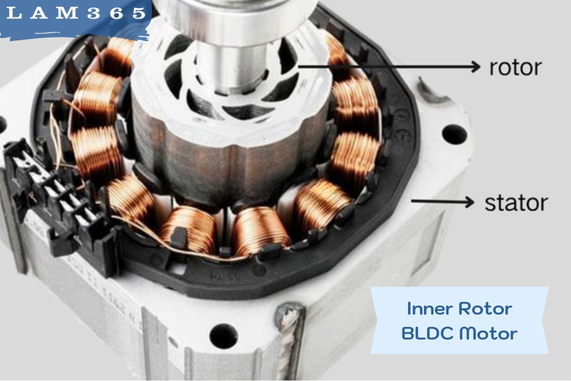

- Inner Rotor BLDC Motor

Here, the rotor sits inside the stator.

This design features:

- Low inertia and fast response

- Compact size and high speed (up to tens of thousands of RPM)

- Easier heat dissipation via the outer shell

Common uses: industrial automation, drones, high-speed spindles, and servo systems.

Core Design Tips:

Use thin silicon steel laminations (e.g. 0.35 mm) to reduce eddy losses at high speed.

Ensure perfect symmetry and balance of the rotor core to handle centrifugal forces.

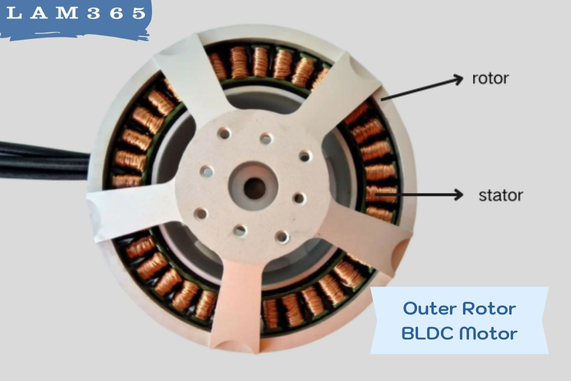

- Outer Rotor BLDC Motor

The rotor wraps around the stator — the whole outer shell rotates.

This configuration provides:

- More poles and higher magnetic flux density

- Greater torque and smoother rotation

- Lower noise but slower acceleration

Common uses: cooling fans, e-bike hub motors, and low-speed drives.

Core Design Tips:

The stator core often uses salient poles to concentrate magnetic flux. Because of the larger air gap radius, higher precision in lamination alignment and insulation is essential.

2. Classification by Sensor Type

The next difference among types of BLDC motor lies in how the controller detects rotor position.

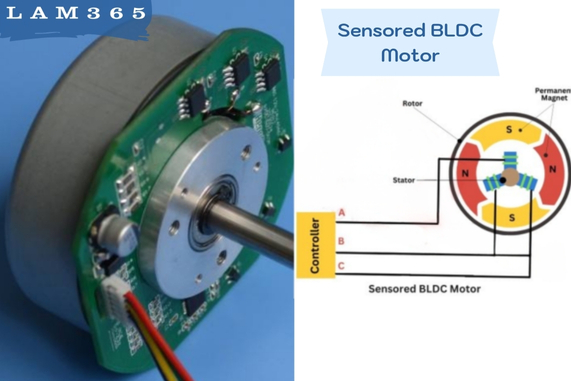

- Sensored BLDC Motor

Equipped with Hall sensors, it can start smoothly and maintain stable control even at low speed.However, sensors add wiring complexity and cost.

Typical applications: servo drives, robots, and precision actuators.

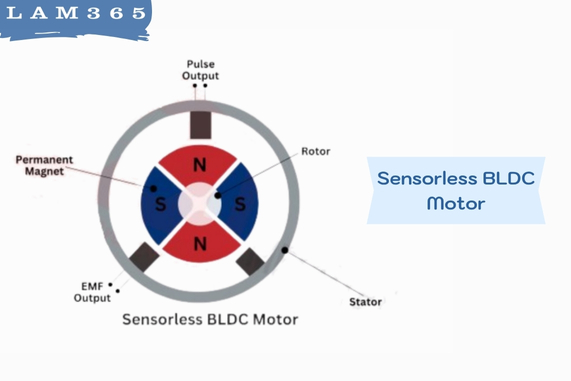

- Sensorless BLDC Motor

This design eliminates physical sensors and estimates rotor position through back-EMF signals.

It’s simpler, smaller, and cheaper — ideal for high-speed products like drones or cooling fans.

The drawback is weaker startup performance under heavy load.

Manufacturing insight:

Stable back-EMF requires consistent air gap and smooth magnetic flux. Poor lamination alignment or uneven slot insulation may distort the signal.

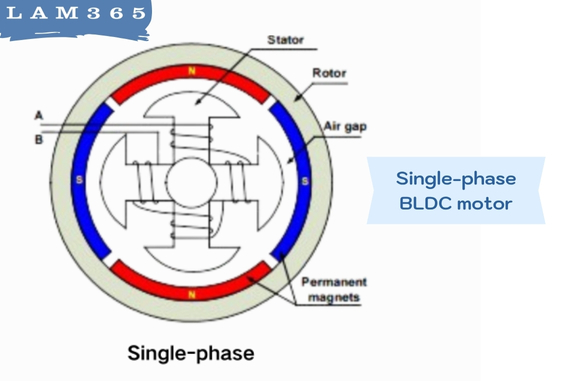

3. Classification by Phase Number

Phase number defines how many independent windings the stator has.

Different BLDC motor types use different phases:

Single-phase BLDC motor: simplest, lowest cost, but less stable.Common in small fans and mini pumps.

Two-phase BLDC motor: smoother torque but rare in mass production.

Three-phase BLDC motor: most common, offering balanced torque, high efficiency, and flexible control.

Core considerations:

Three-phase designs usually use combinations like 12-slot/14-pole or 18-slot/16-pole.These ratios affect the back-EMF waveform and torque ripple.

Precision lamination and uniform stacking ensure balanced magnetic circuits among phases.

4. Classification by Drive Waveform

Among all types of BLDC motor, drive waveform has the biggest influence on smoothness and noise.

- Trapezoidal (Square-Wave) BLDC Motor

Uses simple “six-step commutation.” It’s low-cost, efficient at mid-speed, but generates more vibration and audible noise.

Typical uses: power tools, fans, e-bikes.

Core design note:

High-frequency harmonics in the current cause extra iron losses.

Use thin, low-loss laminations (0.30–0.35 mm) to reduce heat and noise.

- Sine-Wave BLDC Motor

Delivers smooth, quiet rotation by shaping currents into sinusoidal form.

It offers better torque linearity but requires more complex control.

Common uses: robots, compressors, medical devices.

Core design note:

Smooth flux transition needs well-formed slot geometry and even insulation.

Proper slot-pole matching (like 9-slot / 12-pole) ensures a near-sine back-EMF.

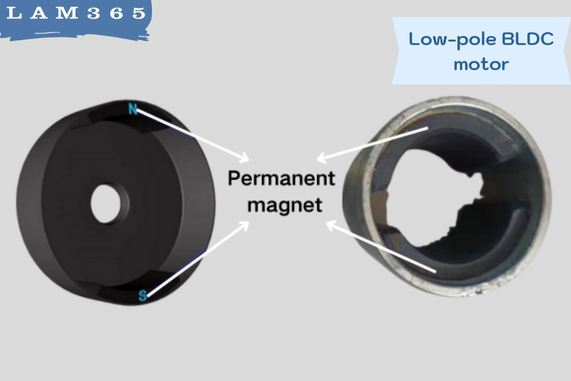

5. Classification by Pole Number

Pole number defines how many magnetic poles the rotor has.

It’s a key factor separating types of BLDC motor between high-speed and high-torque designs.

- Low-pole BLDC motor: fewer magnetic poles, lower switching frequency, suitable for high-speed and light-load devices.

- Multi-pole BLDC motor: more poles, higher torque, smoother motion, but limited top speed.

Applications:

- Low-pole motors — drones, pumps, spindles;

- Multi-pole motors — electric vehicles, servo drives, robotic joints.

Core manufacturing note:

- More poles mean narrower pole pitch and higher flux density.

- That requires tighter lamination tolerances and consistent magnetic insulation to avoid local saturation.

Key Performance Parameters

Every brushless DC motor can be evaluated by several key specs that reflect both electrical and magnetic design:

| Parameter | Meaning | Core Design Impact |

| Rated Voltage | Standard operating voltage | Determines insulation class |

| KV Value (rpm/V) | Speed per volt | Depends on winding turns & magnetic density |

| Torque | Output strength | Affected by flux path and air-gap design |

| Speed (RPM) | Rotational frequency | Related to pole pairs and drive voltage |

| Back-EMF Constant | Voltage induced per speed unit | Linked to flux uniformity |

| Slot-Pole Combination | Stator/rotor design ratio | Affects torque ripple & noise |

| Efficiency | Energy conversion ratio | Determined by lamination loss & control accuracy |

| Noise & Vibration | Mechanical & magnetic balance | Depends on lamination precision |

In short: higher lamination precision = lower loss, lower noise, and higher efficiency.

Working Principle and Advantages

A BLDC motor operates as a synchronous machine:

The controller energizes the stator coils in sequence, forming a rotating magnetic field that pulls the permanent-magnet rotor along.

Unlike brushed motors, electronic commutation replaces mechanical brushes — reducing wear, improving efficiency, and enabling precise control.

Main Advantages:

- No mechanical wear — longer life and cleaner operation.

- Higher efficiency (85–90%) and lower heat loss.

- Higher speed and power density.

- Excellent control precision via electronic feedback.

- Low noise and vibration, especially with sine-wave drive.

- Easier integration with smart controllers or FOC systems.

For motor core manufacturers, this evolution means tighter tolerances, thinner laminations, and better magnetic materials are key to unlocking BLDC performance.

Conclusion: Structure Defines Performance, Core Defines Quality

The types of BLDC motor you choose — inner or outer rotor, sensored or sensorless, three-phase or single-phase, sine-wave or trapezoidal — all determine the motor’s unique “personality.”

Behind every efficient, quiet, and durable brushless DC motor, lies a precisely designed stator and rotor core.

At the end of the day, electronic control defines how the motor moves, but magnetic design defines how well it performs.

If you’re developing or sourcing BLDC motor cores, we can help.

👉 Contact us today — as a professional manufacturer of stator and rotor laminations, we deliver reliable, high-efficiency core solutions for all types of BLDC motor applications.