New Energy Vehicles Motor Lamination Stacks in China

The electric vehicle motor core is the heart of the motor, responsible for converting electrical energy into mechanical energy to drive the vehicle. We are a leading new energy vehicles motor lamination stacks China manufacturer, which can manufacture various stator and rotor laminations for electric motors used in automotive cars.

New Energy Vehicles Electric Motor Cores Products

At present, Lam365 boasts extensive project experience in the development of automotive motor core products. We offer customization for a wide array of new energy pure electric and hybrid model drive motor cores, including compressor cores, automotive power steering motor cores, automotive oil pump motor cores, window motor cores, and numerous other automotive motor products. Our expertise allows us to manufacture various types of motor cores tailored for EV motors.

BLDC Motor Stator for New Automotive

Axial Flux Motor Stator for EV Motor

Permanent Magnet Synchronous Motor Core (PMSM)

New energy vehicle drive motor stator

New energy vehicle Motor Stator and rotor

Self-bonding EV motor lamination stacks

New energy vehicle drive motor core

New energy vehicle refrigeration motor core

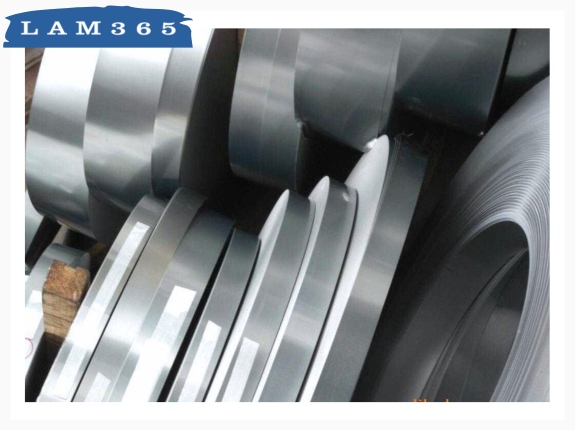

Electrical Steel Material For NEV Motor Core Lamination

At Lam365, we utilize top-quality electrical steel lamination materials sourced from leading suppliers such as Baosteel, Shougang Steel, WISCO Silicon Steel, ANSTEEL in China, as well as JFE Steel and Nippon Steel from Japan. Our extensive and reliable supply chain ensures the consistent availability of high-grade materials essential for manufacturing superior NEV motor cores.

We offer a wide range of thicknesses, from 0.1 to 0.5 mm, to meet diverse design and performance requirements. Our advanced steel slitting machines enable precise cutting and customization, ensuring that each lamination stack meets exact specifications.

High-Speed Progressive Stamping For New Energy Vehicles Motor Lamination

This high-speed progressive stamping process involves feeding a continuous strip of electrical steel into a progressive die, where multiple stamping operations are performed simultaneously at high speeds. Each stage of the die progressively shapes, punches, and trims the material, resulting in highly accurate and consistent motor laminations.

We specialize in designing and manufacturing both single-row and two-row progressive dies, tailored to meet specific project requirements. Our expertise in die design ensures optimal material utilization and minimal waste, leading to cost-effective production.

Prototype Automobile Electric Motor Core

We offer prototype electric drive motor cores for automobile vehicles with a minimum order quantity (MOQ) of just one piece. This service is ideal for customers looking to test and validate their motor designs before full-scale production. We provide laser cutting and wire EDM services.

Other Products

Power Tool Motor Core

FAQs

Electric vehicles (EVs) typically use one of three types of motors: DC brushless motors, permanent magnet synchronous motors (PMSM), and induction motors.

DC brushless motors are known for their efficiency and reliability. PMSMs offer high performance and efficiency, making them popular in modern EVs. Induction motors, while less common, are robust and can provide high torque.

The choice of motor depends on the specific performance requirements and design of the EV.

For EV motor cores, thin gauge electrical steel with thicknesses ranging from 0.1mm to 0.35mm is commonly used.

This thin gauge material reduces core losses and improves efficiency, making it ideal for high-performance electric motors.

Lam365 can source top-quality thin gauge electrical steel to ensure optimal performance and durability in EV motor applications. such as JFE electrical thin steel sheets with thicknesses of 0.20mm, 0.25mm, and 0.30mm.

Choose Us as Your China Manufacturer of New Energy Vehicles Motor Lamination

Ready to enhance the performance and efficiency of your electric vehicles? Choose us as your trusted China manufacturer for new energy vehicle motor laminations. Our factory is equipped with 15 sets of high-speed punching machines and a professional QC team and have a long-term cooperative and stable high-end customer base. Contact us today to discuss your project requirements and request a quote.