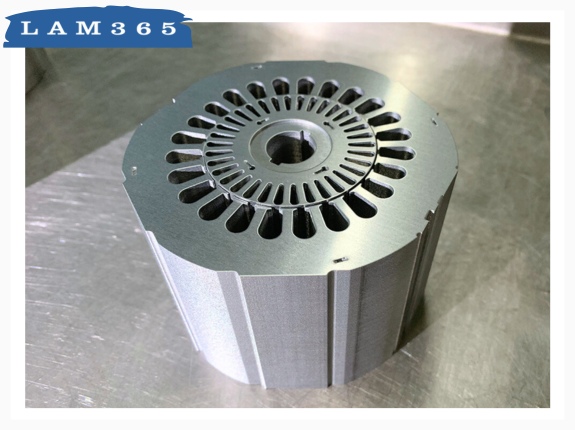

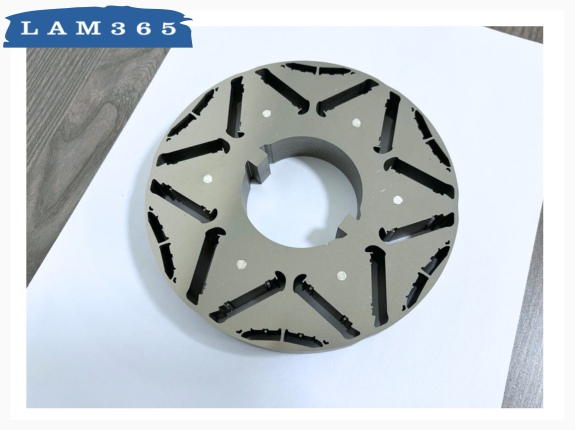

Self-Bonding Lamination Stacks in China

Full-face bonding — our most non-damaging technique in producing stator and rotor cores.

Self-bonding lamination stacks, also known as full-face bonding, offer exceptional performance and reliability in motor manufacturing. This advanced joining technique ensures enhanced structural integrity, reduced vibration, and superior thermal and electrical conductivity.

Self-bonding provides a cleaner and more environmentally friendly solution by eliminating the need for interlocking or welding. We also provide glue bonding lamination stacks.

Self-Bonding Electrical Steel Laminations Technology

Self-bonded motor core is an innovative stator core manufacturing process. In fact, self-bonded iron core can be regarded as a variant of the bonded iron core.

- It uses a special functional coating to tightly bond the stator core pieces to achieve an integral connection. Through the self-bonding process, the structural strength and geometric tolerance of the stator core can be effectively improved.

- The key to this lamination bonding process is the correct selection and use of self-adhesive coatings, as well as strict control to ensure the quality and stability of the stator core.

- The self-bonded core process uses special coatings and high-temperature curing to tightly bond the core sheets, thereby significantly improving the strength of the overall structure.

Self-Bonding Lamination Stacks Products

Ultra-thin electrical steel sheets are difficult to form riveting points or interlocking points, and laser welding may cause local conduction, which is detrimental to motor performance. Therefore, self-bonded iron cores have become an ideal choice to solve the problem of lamination and assembly of ultra-thin silicon steel sheets.

Advantages of Full-Surface Bonding with Backlack

4. Improved Thermal Conductivity

The full-surface bonding enhances thermal conductivity, allowing for better heat dissipation and improved overall motor performance.

5. Reduced Vibrations and Noise

This method significantly reduces vibrations and noise, leading to quieter motor operation and enhanced user experience.

6. Increased Vehicle Range

For electric vehicles, the improved efficiency and reduced energy losses from full-surface bonding contribute to an increased vehicle range, making it a preferred choice for modern automotive applications.

1. Freedom of Design

Full-surface bonding with Backlack allows for greater flexibility in motor design. Engineers can create intricate and optimized designs without the constraints imposed by traditional bonding methods.

2. Mechanical Stability and Dimensional Accuracy

This bonding technique ensures high mechanical stability and precise dimensional accuracy. The result is robust and reliable motor cores that maintain their structural integrity under various operating conditions.

3. Maintenance of Magnetic Properties

Backlack bonding preserves the magnetic properties of the laminations, ensuring optimal performance and efficiency of the motor.

Conventional stacking techniques for electrical steel lamination stacks

Laser welding

This technique uses a high-powered laser to weld the laminations together at specific points. Laser welding provides a strong bond and precise alignment but can introduce localized heating.

Interlocking

Interlocking involves creating tabs and slots on the edges of the laminations, allowing them to snap together without the need for additional bonding agents.

Riveting

Riveting uses mechanical fasteners to hold the laminations together. This method is reliable and easy to implement but can add weight and create stress points within the stack.

FAQs

Ensuring the consistency of coating thickness on the surface of the silicon steel sheet is a primary challenge. Additionally, managing the storage and timeliness of bonding varnish demands precision processing and testing equipment. These factors are crucial to maintaining the high-quality standards and performance of self-bonding lamination stacks.

The adhesive materials of self-bonding motor cores are typically EB540, EB546, EB548, EB549, and EB549 fast.

EB549 and EB549 fast are primarily used in new energy vehicle drive motors and small to medium-sized motor cores, providing excellent performance and reliability in these applications.

Self-bonding lamination stacks are most commonly used in new energy vehicle motors. They are also ideal for various other applications, including industrial motors, traction motors, renewable energy systems, and high-performance electric motors, offering enhanced efficiency, reduced noise, and improved durability across different sectors.

Reliable Self-Bonding Lamination Stack China Manufacturer!

For superior self-bonding lamination stacks, trust our expertise and advanced manufacturing capabilities. Our team is ready to assist you with customized solutions tailored to your specific motor requirements. Contact us today to learn more about our adhesive bonding services, request a quote, or schedule a consultation.